HVAC Machinery & Accessories

Most of the equipment we sell can be used in the heating ventilating and air conditioning industry but there are specific tools that are only used for HVAC fabrication and installation. The leader in the field of HVAC equipment is The Lockformer Co, makers of hand tools, to the Vulcan Plasma cutting system.

As an industry-focused machinery manufacturer, our mission is to deliver the latest designs in plasma cutting system technology better than anyone else. The innovative Vulcan 1000B, whose revised features incorporate almost 20 years of engineering experience, does just that. In the HVAC industry, where labor costs are high and work is hard, physical and demanding (just like our machinery), the Vulcan 1000B’s performance advantage is real proof that quality and reliability matter.

The Roper Whitney No. 622 has a 7″ deep throat and a capacity of 24 gauge mild steel. By changing the rolls it will perform turning, burring, wiring, elbow edging, flanging and flattening operations as well as crimping, beading, ogee bead, furnace collars, and offsetting. Benoit Sheet Metal Equipment also supplies a special set of flattening and 3/8″ bead rolls. It may be operated to feed from left to right, both with a clockwise rotation of the handle. The model 622 includes roll nuts, gauges, bench mount stand and wrench.

The Roper Whitney No. 622 has a 7″ deep throat and a capacity of 24 gauge mild steel. By changing the rolls it will perform turning, burring, wiring, elbow edging, flanging and flattening operations as well as crimping, beading, ogee bead, furnace collars, and offsetting. Benoit Sheet Metal Equipment also supplies a special set of flattening and 3/8″ bead rolls. It may be operated to feed from left to right, both with a clockwise rotation of the handle. The model 622 includes roll nuts, gauges, bench mount stand and wrench.

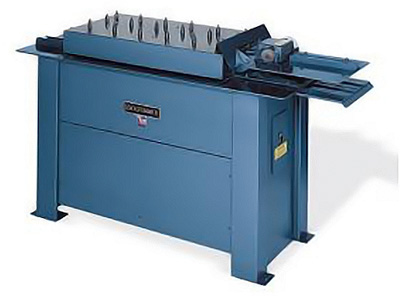

For reinforced “S” and drive cleats plus two optional auxiliary sheet-edge operations. Combination “S” and drive cleat scrap cutter attachment available. Every 9-station Triplex Cleatformer incorporates Lockformer’s tri-plate construction and reinforced flat “S” cleat. The inboard “S” and drive cleat roll sets are furnished as standard between plate housings. Extended shafts on both sides of the machine can accommodate many other sheet-edge operations, including the 20 gauge Pittsburgh Lock and the Button Punch Snap Lock.

Triplex construction provides two inboard forming positions supported between side plates. This bearing support on both sides of the profile controls deflection encountered when running heavy-gauge material or unusually intricate shapes.

Shown with optional “S” and drive cleat scrap cutter attachment.