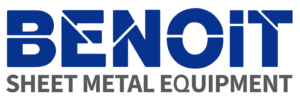

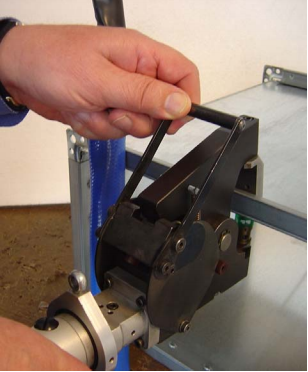

The “Clinchlok” joint is formed when the upper tooling squeezes the two ply of material joined between the punch and die. The amount of squeeze is very important to the strength of the Cinchlok joint and to the life expectancy of the punch and die. Note that the die is of a very special design that allows the Clinchlok to “mushroom”. The punch is also a special design and unlike a normal punch the edge of the punch is not sharp, but is rounded. This is known as the punch tip radius. Neither the punch or die can be sharpened.

If different thicknesses are to be joined, the best results occur when the thicker material is on the upper (punch) side of the two ply. The thicker material should not be more than twice the thickness of the thinner material. The combined thickness of the two ply should not exceed the combined maximum thickness recommended for the die. Other materials can be joined with the SURELOK II as long as they are not harder than commercial quality mild steel. In most cases both ply should be of the same hardness. If a different hardness is used for each ply (not recommended) the harder material should be on the upper (punch side) if possible.

- Display 15 Products per page